Yeah that's right Mike, the body is the bulk of the work. There are a hell of a lot of other bits to do though, so it's more like 1/2 the battle

Anyway, today yielded results. First was a trip to the rolling road dyno:

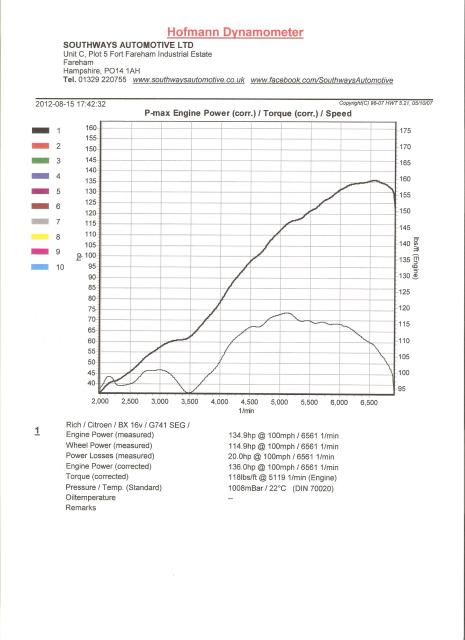

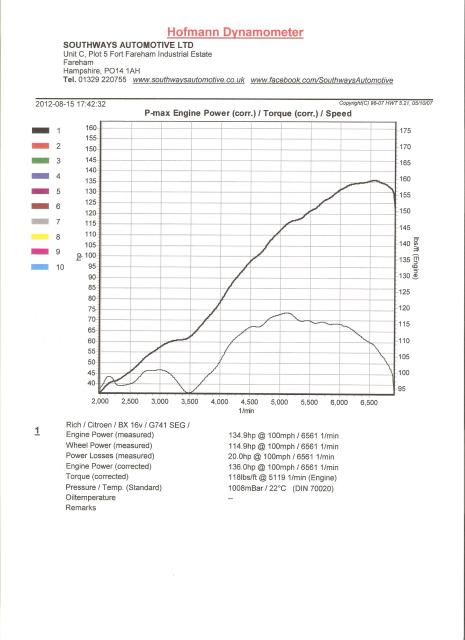

Results not so great:

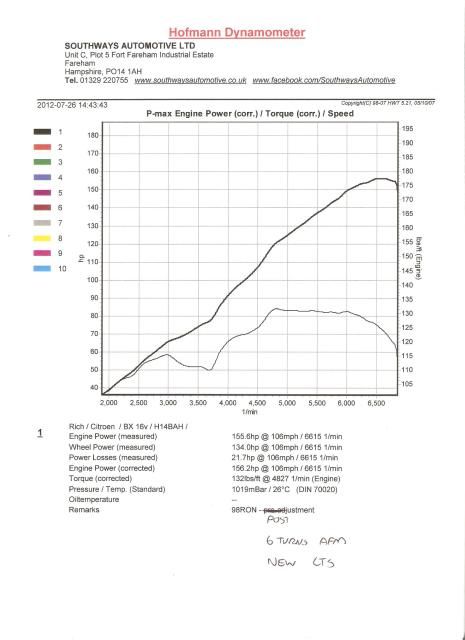

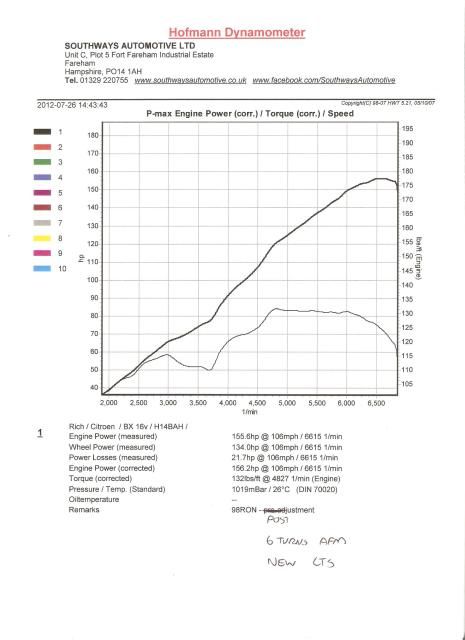

Compare it to the only other 16v I've put on there - mine, which is pretty much standard these days:

(Don't read too much into the 98RON thing - it makes very little difference.)

This could be down to old fuel - I'm waiting to find out when it was last topped up and with what, as supermarket fuel seems to go off quicker than the branded stuff (could all be in my head - it all comes from the same place afterall!). Worringly, around 3500rpm the AFR monitor was reading 15.9

It basically means it's running very lean, which is the sort of behaviour that can melt things inside engines. So that will need addressing. Generally, the engine sounds ropey and isn't happy running. I'm pretty confident I could sort it out - compression test next will give me more info to hand, but I think the reason it sounds crap is probably the tappets needing a strip & refurb. If I fix it up engine will come out anyway and was going to do cambelt so it's no real hardship to whip the cams out and sort the tappets at the same time - it's just time consuming; redressing 16 hydraulic buckets takes days off your life!

Incidentally, anyone reading this with a 16v - I'll dyno it FOC if you bring it down; I'm keen to learn patterns on the rollers with different examples and specs.

I'd heard the car wasn't exactly a scorcher previously from more than one source, so although the results weren't a surprise I was still feeling a tad deflated. I was expecting the worst when I put it on the ramp:

Initially, I went straight to the zone that many have already told me has written the car off....

Followed by....

Now that looks shocking (not just the attempted welding of the subframe) but......the main rail isn't the part that's massively affected. Although there is a bit that needs attention, the larger part that is unseaming itself from the rail is the closing panel that forms part of the inner wheel arch. That isn't as structural as the rail, although it will reinforce it. But this is good news from this respect. It's still an engine and subframe out job, so a pretty massive job, but it's not what I would class as enough to write a car with potential off. So I'd already decided that this rot is not the killer of the car, if I do decide that it's a no-go.

Happily the other side is better, though desperately needing treatment:

The leak you can see is from the octopus - it's pissing out of one of the returns. The brake lines to the front calipers are also shot, so when you touch the brakes it gushes out. And when it's not gushing, it's still dripping all over BMW M3s:

Luckily, sills look good. Certainly no worse than my red one, or most other BXs I look under:

Haven't found anything horrific anywhere else either:

CV boot *might* need attention though:

The only thing I hate to say here (and it's no dig at Tim) but it's a prime example of a car being kept clean and polished and that being regarded as 'looking after your pride and joy' when underneath it wasn't receiving the attention it needed. It might be with a new car that you're fighting depreciation with, but as a car ages the body becomes less important and the underneath and mechanicals start to take centre stage. I'm not quite sure why or how or who, but the guts of the car just don't seem to have had that enthusiasts touch, even if the exterior clearly has.

It's no dig at Matt either, he hasn't owned the car long enough to really influence it. I know he had plans for the car and at one point favoured it to his ph1. I can almost guess the reason is because his ph1 will drive a lot better than this one, and that's without having driven his ph1.

Overall I would class it as a positive day. I'm still not 100% sold on what I'm doing with it - I need to go round the car and make a list of everything that needs doing. If I'm going to sort the car, I'll do it properly. No half-arsed jobs, properly or not at all.

[quote=citsncycles]As you said though, lots of time needed to devote to this one, although worth it if you have the time and skills - I hate to think of the cost if you paid a garage to do it [/quote]

That's the thing Mike - I would imagine for a garage to put this right (and this is speaking as someone who works at a garage) you're looking at around £2k minimum to carry out all the work. Luckily, between time with my young and seemingly ever-growing family, the Sierra I'm recomissioning for my father-in-law, the BX GT I'm restoring for my dad and the kit car I'm trying to build, I might have the odd spare 2 minutes to remove a wing bolt on this and slowly do it over time in the evenings